Wooden Acoustic Ceiling Panels Manufacturer Wood Acoustic Panels Ceiling Installation

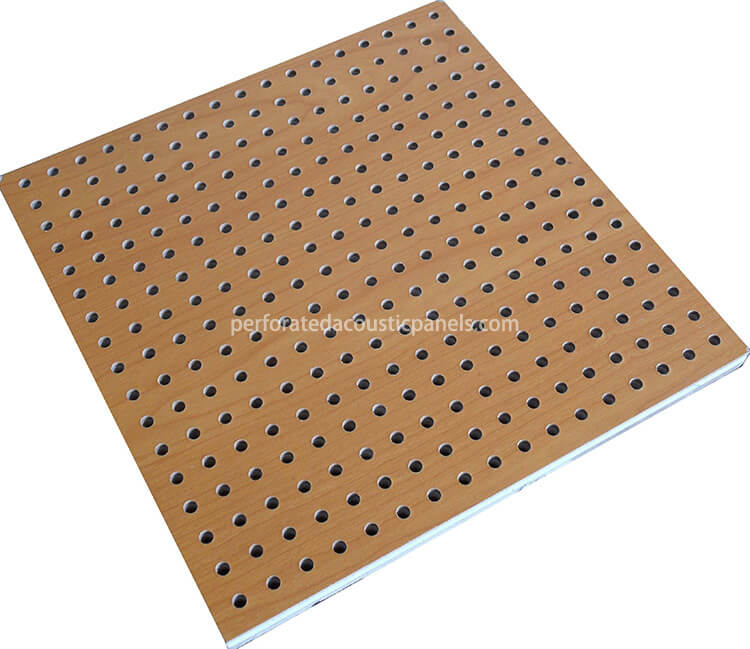

Our acoustic perforated panel uses beautiful wood panels for exquisite wall and ceiling treatments. We are committed to creating high-performance acoustic products with excellent appearance. Wooden acoustic ceiling panels have a variety of configurations to meet all acoustic requirements. The wooden acoustical ceiling panel balances the reflection and absorption of sound through perforations. Combining acoustic wood ceiling tiles with absorbent backings provides excellent acoustic performance in aesthetic and pleasing wall and ceiling finishes.

Wood veneer is cut into thin slices from hand-selected logs, and then pasted on flame retardant medium density fiberboard by perforated ceiling panels suppliers. Two layers of UV varnish are then applied during the manufacturing process. This ensures that the quality of each panel of each project is consistent.

Wooden Acoustic Ceiling Panels

Pattern: according to design

Thickness: 12mm / 15mm (16mm) / 18mm

Surface: melamine/wood veneer/varnish/spray paint/HPL

Core material: E0 MDF/B1 MDF/Mg composite/NF gold

Backing: acoustic fleece

Install: aluminum keel and clamps, wooden structure, gun nails, acoustic panels ceiling installation

Function: environmental protection, sound absorption, flame retardant

Use different kinds of large-size wooden acoustic ceiling panels on the ceiling, instead of using it on the infeasible continuous roof, and use standardized roof panels in the visible profile, semi-hidden, hidden and feasible hidden versions. Acoustic perforated panels are usually used on the size of 600×1200, 600×600, 2400×1200, and 2400x600mm. The thickness of wooden acoustical ceiling panels is 12mm, 15mm, and 18mm.

Materials and finishes

The support material is mainly MDF in standard or fireproof versions. The surface treatment can be raw, melamine, veneer, varnished or painted. Provide other options upon request. The wooden acoustic ceiling panel can be bonded to the back, and as an option, an acoustic veil can be combined to improve the sound absorption quality of the panel.

Cleaning and maintenance

After installation, the acoustic wood ceiling tile should be treated like any exquisite furniture. The final cleaning with a soft cloth and any good furniture polish will enhance and retain the gloss of the finish. The microperforated acoustic panels can be vacuumed with natural bristles without damage. Avoid using short, hard bristles to clean the head, otherwise it may be damaged. After removing the dust, use a high-quality furniture polish (such as lemon oil) to wipe the panel to restore the beauty of the woods.

Do not spray polish directly on the perforated ceiling tiles. Instead, apply the polish to a soft lint-free cloth, and then gently wipe the panel. At all costs, avoid using water or damp cloth, as this may affect the stability of the veneer. The cleaning interval will depend on the condition of the building. It is recommended to clean it at least once a year, but this may depend on your building conditions. Regular maintenance will maintain the appearance and performance of wooden acoustic ceiling panels for many years to come.